HOW DOES CloEE WORK?

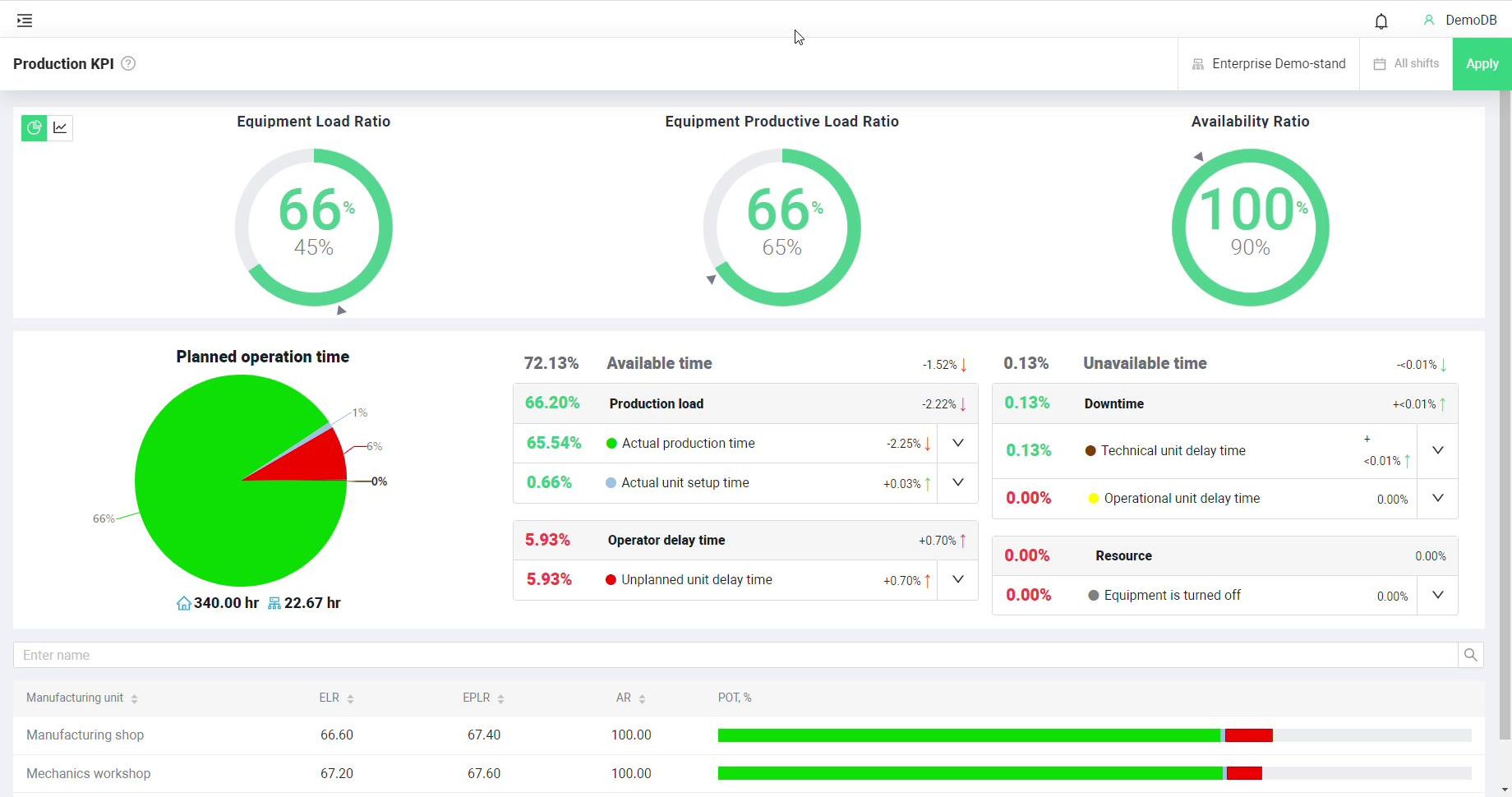

CloEE collects data from any type of industrial equipment and gathers analytics and reports for OEE improvements, energy savings, and CO2 reduction. It places your operational information at your fingertips, anywhere and at any time, from dashboards to timelines to interactive shop floor layouts, using a modern Web client.

WITH CloEE YOU CAN

Increase Overall Equipment Efficiency (or utilization) of every industrial machine by at least 20% in a few clicks

Make Industry 4.0 fast to adopt and affordable for any enterprise

Decrease CO₂ emissions by minimizing the number of required machine tools

Build a global manufacturing network helping to produce anything, anywhere, remotely

Attract further generations of millennials by digital machining and manufacturing

Industries CloEE serves

Automotive

Heavy machinery

Oil & gas equipment

Shipbuilding

Consumer goods & electronics

Aerospace & defense

Pharmaceutical

Solar & Wind power plants

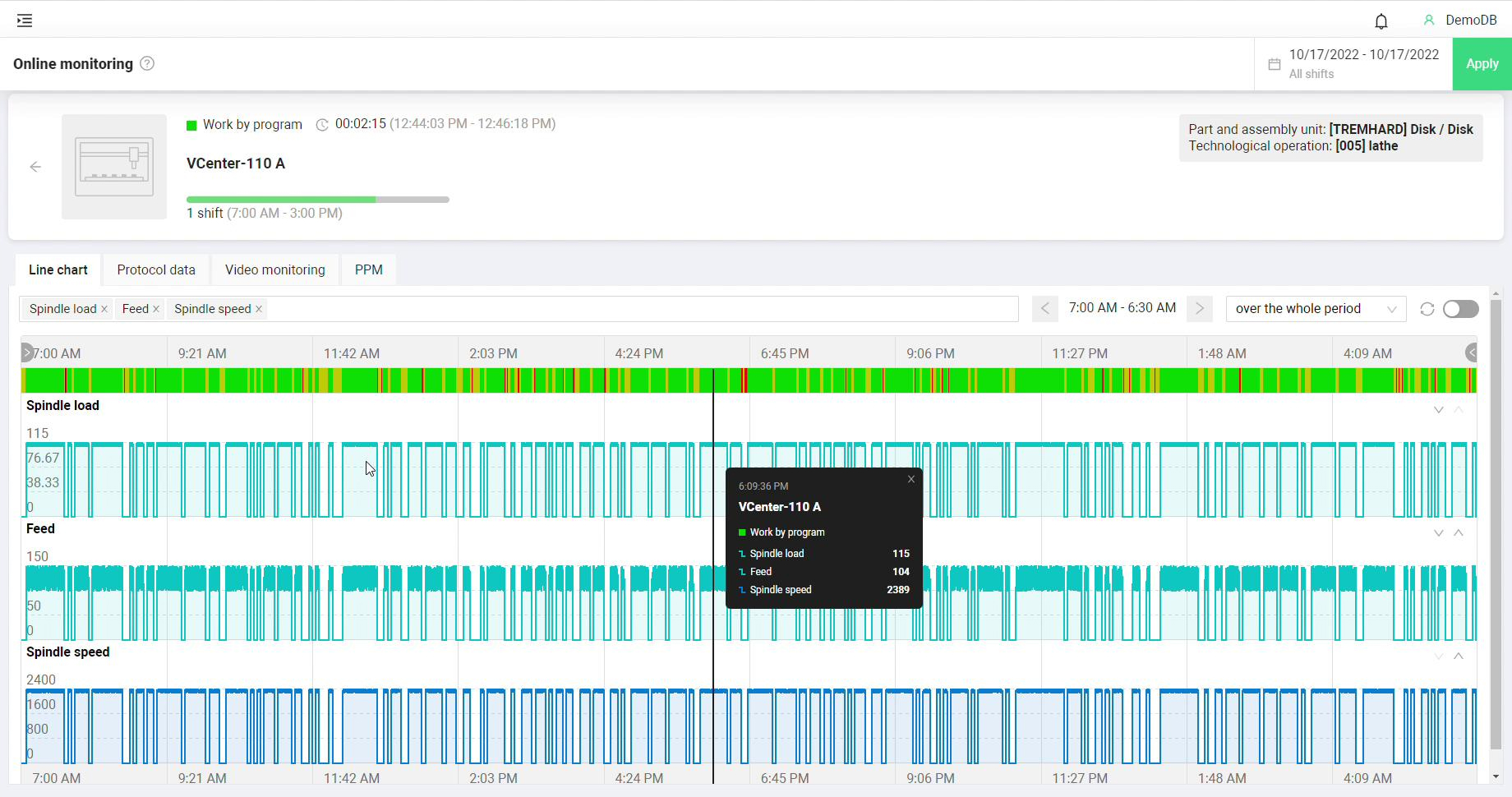

Online monitoring

Online monitoring

DNC communication & NC program management

DNC communication & NC program management

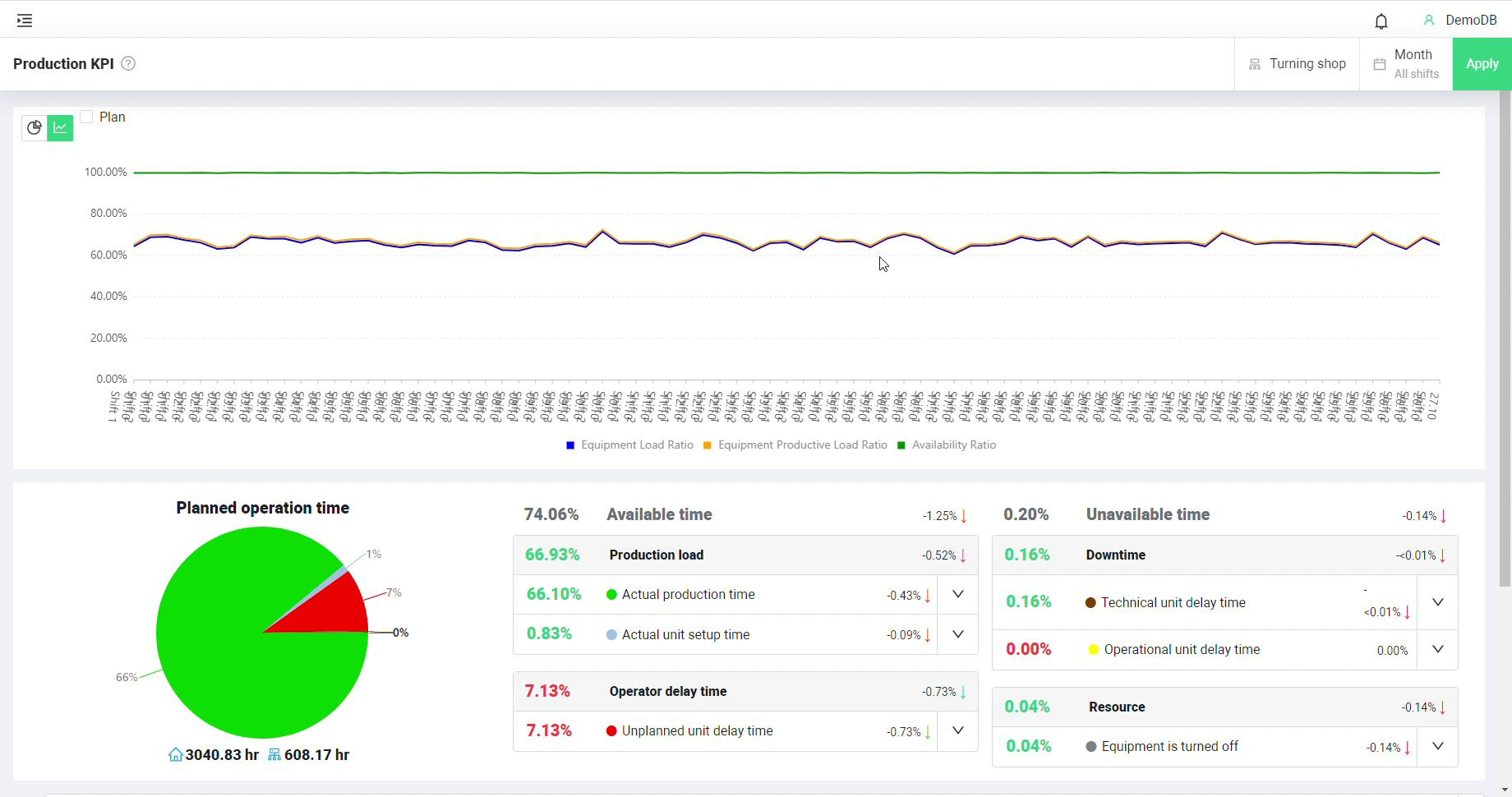

Production monitoring

Production monitoring

CO2 emissions monitoring

CO2 emissions monitoring

KEY FEATURES

The CloEE solution is ideal for both large and small and medium-sized businesses. We are focusing on improved development. CloEE represents our vast experience formalized into a focused product containing the most important, accessible, and efficient elements. Exactly what you need.

API connection

Fast project implementation (complete setup in an hour)

High mobility – convenient access to all the relevant information from any device

No web or database servers to maintain

Easy integration with any 3rd Party system

Automatic software updates included

Quick data recovery & loss prevention for a wide array of emergency scenarios

Online monitoring

Online monitoring

DNC communication & NC program management

DNC communication & NC program management

Production monitoring

Production monitoring

CO2 emissions monitoring

CO2 emissions monitoring

Efficiency improvement of Machine Building Enterprise in Ukraine

MAGMA

MACHINE BUILDING ENTERPRISE

Production: spare parts, custom built equipment, handling equipment

Industries: metallurgical, mining and coke industries, sea and river ports

TASK:

To decrease COVID-19 pandemic effect and keep completion for strategically important orders on-time

Magma LLC was able to prioritise and redistribute orders within their factory based on urgency while taking some machines offline — thus freeing up staff

Results

of the floor staff could be released from the workshop and sent home to work remotely

of the managerial staff continue to monitor the status of order fulfillment online from their homes

Solution

MAGMA‘s management evaluated the equipment workload for strategically important orders

Tasks were redistributed between equipment and personnel

Some of the machines were completely stopped, remaining machines were loaded to approach 100% capacity

Enhanced the Capacity Planning for Gear manufacturing company

MURUGAPPA

SHANTHI GEARS

TASK:

- Higher production efficiency due to the order portfolio growth and expansion of the business geography

- Higher transparency of production business processes

- Detection of equipment downtime and record of the operating time

To decrease COVID-19 pandemic effect and keep completion for strategically important orders on-time

Machines connected: 120+

EQUIPMENT TYPE:

Machines with CNC - Fanuc, HAAS, Siemens, REISHAUER, PLC and Legacy machines

Project complexity: The main issue was connecting heterogeneous machines with the unified platform to understand the effective load of each machine. The management could not effectively influence this situation due to the opacity of the production information model and capacity planning

Results

availability time improved

organizational downtime decrease

the Return Of Investment (ROI)

Solution

Connectivity with CNC, legacy machines. Wide acceptance for heterogenous machines

It helped SGL for capacity planning (as they are not in mass production, they produce basis on order to make)

Organizing the storage and transfer of the NC program to the machines

Machines produce more parts due to increased machine availability

Real-time monitoring and MES integration

TSK

A KOMAX GROUP COMPANY

TASK:

- Removing human factor during generation of reports

- Measuring equipment utilization

- Compare equipment utilization by shifts

- Integration with MES system

To decrease COVID-19 pandemic effect and keep completion for strategically important orders on-time

Machines connected: 14

EQUIPMENT TYPE:

Machines with NC: Fanuc, Haas

Results

equipment load increase

overall efficiency increase

Solution

Utilization of machines is reported

Machine downtime and total downtimes are reported

The number of produced parts is calculated

Production times for the parts are calculated

TSK decided to deploy CloEE at 5 production sites

HOW CAN CloEE HELP YOUR BUSINESS

BE GREENER?

Determining a product’s carbon footprint helps to benchmark decarbonization efforts, but is also challenging due to the lack of data transparency.

The system enables enterprises to decrease equipment electricity consumption through efficient utilization while also decreasing scrap, making production more environmentally friendly by using fewer resources, and decreasing production’s CO2 footprint.

We offer one tool to simplify a complex topic and help you reduce global warming and make your carbon footprint visible. Calculate the Carbon Dioxide Equivalent emissions of your equipment with CloEE — your carbon footprint and climate impact are now displayed in real time on your dashboard.

CloEE ARCHITECTURE

SUPPORTED CONNECTIVITY TO MACHINE VENDORS

THREE STEPS TO A NEW LEVEL OF EFFICIENCY

Leave a request on the site and fill out the short questionnaire sent by a personal success manager

Install the Edge adapter and connect machines with ease to use the wizard

Connect to the cloud through a web browser, tablet, or mobile phone. All set. CloEE is ready to use

CloEE — SAFETY AND RELIABILITY

DISTRIBUTED GEOGRAPHY

Cloud technology provides the ability to deploy the solution in different regions worldwide. Providing the necessary geographic scale in line with user requirements.

RELIABILITY

Servers provide reliable data storage at on-site locations, as well as guarantee maximum stability following the strict requirements.

HIGH SLA AND BACKUP

Compliance with international quality standards while providing high availability, rapid disaster recovery, and data backup. Protecting against failures within data centers. VM SLA 99,99% PROTECTION FROM fire, power, cooling disruption, and flood.

FREQUENTLY ASKED QUESTIONS

What if I want more functionality?

Leave a request, and let us tell you about CloEE Enterprise. This version of CloEE also includes DNC communication & NC program management, computerized maintenance, and power consumption monitoring.

Why do I need to install the Edge client?

Edge is required to connect your closed machine network to our cloud server. It also buffers data in case of connection failure.

Where is my data stored?

All data is stored in the Hetzner European data center and is securely encrypted. Our software does not interfere with machine operation; it simply reads the data, with safety confirmed by numerous machine manufacturers.

Industry 4.0 is the DNA of the CloEE team

The CloEE team possess 5+ years of experience working with Industry 4.0 projects and has uplifted 400 large industrial enterprises in 25 countries. We know how to realize the potential of OEE to raise the mark for industrial and professional equipment above 70%. Over the years, our engineers and developers have compiled a basic set of priority reports that shows comprehensive results in the cloud version of the monitoring system.

If you need to see more reports and data, contact us, and let’s discuss the implementation of CloEE Enterprise.

Engineering knowledge and machine tools maintenance roots

Machines connectivity and data models expertise in Discrete manufacturing

Industry 4.0 Software development and deployment expertise

Customer success manager & service desk for prompt and effective tech support